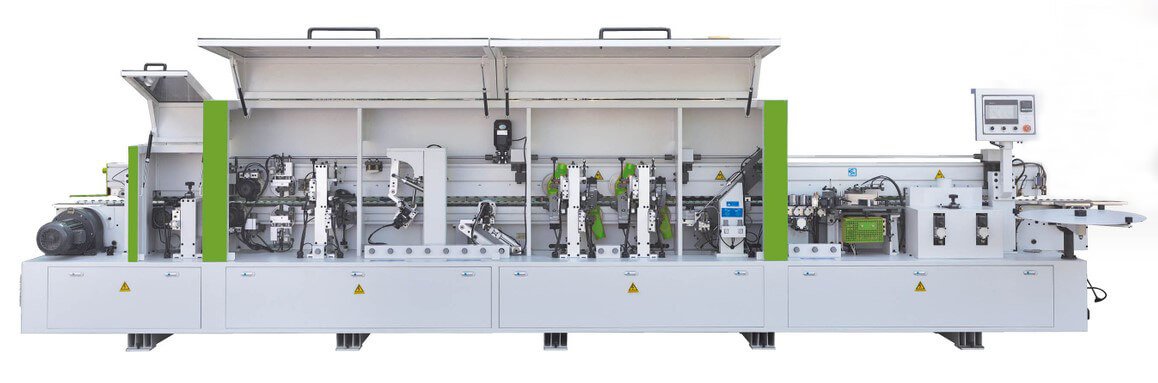

Let's take a closer look at the functions of the edge banding machine:

1. Trimming

The first essential function of the edge banding machine is trimming. Trimming involves cutting the excess edge banding material to the right size. This is done by using a trimming cutter located at the beginning of the machine. The trimming process is automated, making it efficient and accurate.

2. Gluing

After the edge banding material has been trimmed, it is then glued to the edge of the furniture panel. The edge banding machine has a glue dispensing system that applies the glue to the edge of the furniture panel. The glue used is typically a hot-melt adhesive, which is activated by heat. The machine also has an automatic feeding system that ensures that the glue is applied evenly to the entire edge of the panel.

3. Cutting

Once the edge banding material has been glued to the edge of the furniture panel, the excess material is cut off. This is done by using a cutting saw located at the end of the machine. The cutting process is automated and precise, ensuring that the edge banding material fits perfectly onto the furniture panel.

4. Smoothing

The final function of the edge banding machine is smoothing. After the edge banding material has been cut, it is then smoothed to remove any rough edges or imperfections. The smoothing process is done using a sanding wheel located at the end of the machine. The sanding process is automated, making it efficient and precise.

Overall, the edge banding machine is an essential tool in the furniture production line. It ensures that the edge banding material fits precisely onto the furniture panel, making the end product look professional and complete. It is important to note that the edge banding machine is just one component of the banding sheet production line. Other components include a panel saw, drilling machine, and assembling machine.

In conclusion, if you are in the furniture production business, you need to invest in an excellent edge banding machine. The machine guarantees efficiency, accuracy, and professionalism, which are necessary for your business's success.