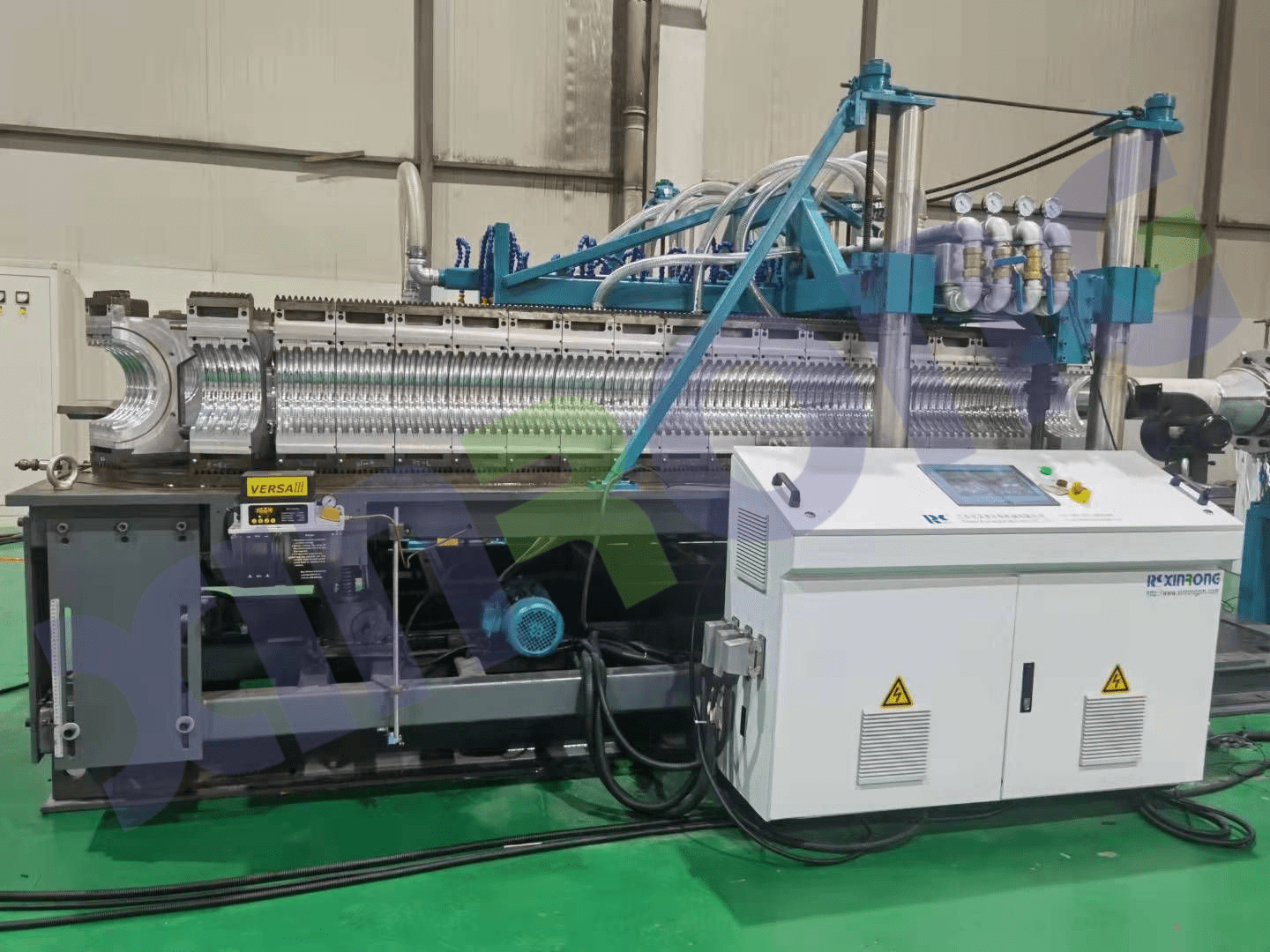

Properties of the HDPE Double Wall Corrugated Pipe Extrusion Line

The HDPE double wall corrugated pipe extrusion line is a fully computer-controlled machine designed to produce drainage pipes. It features a high and stable output capacity, making it an efficient choice for commercial production. With its highly automated operation, the extrusion line is easy to operate, minimizing labor costs and reducing the risk of errors.

The line is designed to manufacture high-quality HDPE pipes, and you can choose either a high efficient single screw extruder for HDPE or a conical twin-screw extruder or parallel twin-screw extruder for PVC, depending on your production needs.

Benefits of the HDPE Double Wall Corrugated Pipe Extrusion Line

1. High production capacity

The HDPE double wall corrugated pipe extrusion line features a high and stable output capacity, making it an efficient choice for commercial production.

2. Automated operation

The extrusion line is fully computer-controlled, featuring highly automated operation. This reduces the need for manual labor, minimizing the chances of errors and ensuring consistent product quality.

3. High-quality pipes

The HDPE double wall corrugated pipe extrusion line is designed to manufacture high-quality pipes that meet international standards.

Conclusion

If you're looking for a high-quality extrusion line to produce HDPE double wall corrugated pipes, then the HDPE double wall corrugated pipe extrusion line from JEEBO Machinery is an excellent choice. JEEBO Machinery is a leading WPC pipe machine supplier in China with a proven track record of supplying high-quality machinery to clients worldwide. Contact JEEBO Machinery for more information on their range of WPC machines.