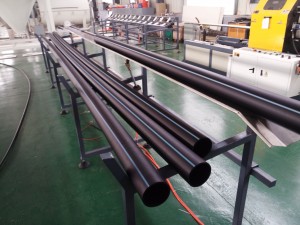

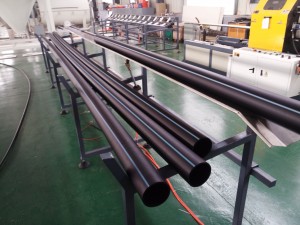

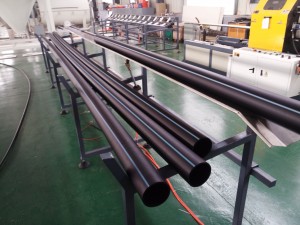

1.Machine introductions for PP PE PPR pipe production line: Application of pe pipe: With the PE pipe production line, you can extrude high quality large diameter water and gas supply pipes .This pipes produced by our line have excellent stiffness and flexibility ,resistance to creep deformation ,excellent heat-linkage .Large dismeter HDPE pipes start to play very important role in the city water and gas supply systems. Machine advantages of pe pipe production line : This line is assembled lattice or spiral mould, new type calibration unit and spraying cooling bath. Advanced PLC control system and large chromatic liquid-crystal screen make the operation more convenient ,having a friendly human-machine interface.

2. different models of PP PE PPR pipe production line for different diameter: | Model | Diameter(mm) | Marking line machine model | Max.output(kg/h) |

| SJ-65B | φ110 | SJ-25 | 90-180 |

| SJ-90B | φ200 | SJ-30 | 200-320 |

| SJ-120B | φ400 | SJ-30 | 320-500 |

| SJ-150B | φ630 | SJ-30 | 550-700 |

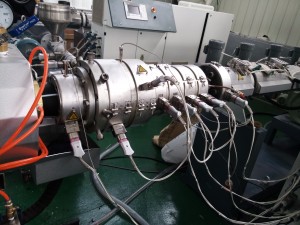

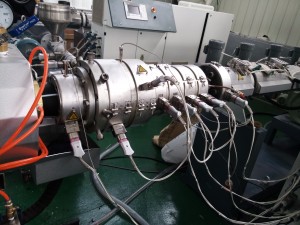

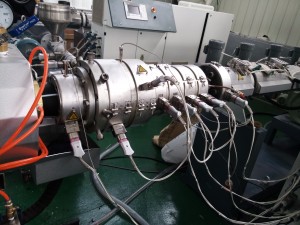

3, Machine line consists of PE pipe production line: The production line consists of control system ,extruder,mould,calibration unit,haul-off unit,planetary cutter and stacker. 1, Main extruder: single screw extruder

2, co-extruder: SJ30 extruder for marking line

3, die head: different size may use different die head

4, vacuum cooling tank: 6 meter length

5, spraying water tank: 6 meter length, for big diameter, we may need to equip 2 sets or 3 sets of spraying water tank

6, haul off machine: for different diameter, we may equip different type of haul off machine, such as double caterpillar type, three caterpillar type, four caterpillar type

7, cutting machine: high quality cutting machine for non-dust cutting

8. product stacker: 6 meter length

2, co-extruder: SJ30 extruder for marking line

2, co-extruder: SJ30 extruder for marking line  3, die head: different size may use different die head

3, die head: different size may use different die head  4, vacuum cooling tank: 6 meter length

4, vacuum cooling tank: 6 meter length  5, spraying water tank: 6 meter length, for big diameter, we may need to equip 2 sets or 3 sets of spraying water tank

5, spraying water tank: 6 meter length, for big diameter, we may need to equip 2 sets or 3 sets of spraying water tank  6, haul off machine: for different diameter, we may equip different type of haul off machine, such as double caterpillar type, three caterpillar type, four caterpillar type

6, haul off machine: for different diameter, we may equip different type of haul off machine, such as double caterpillar type, three caterpillar type, four caterpillar type  7, cutting machine: high quality cutting machine for non-dust cutting

7, cutting machine: high quality cutting machine for non-dust cutting  8. product stacker: 6 meter length

8. product stacker: 6 meter length

2, co-extruder: SJ30 extruder for marking line

2, co-extruder: SJ30 extruder for marking line  3, die head: different size may use different die head

3, die head: different size may use different die head  4, vacuum cooling tank: 6 meter length

4, vacuum cooling tank: 6 meter length  5, spraying water tank: 6 meter length, for big diameter, we may need to equip 2 sets or 3 sets of spraying water tank

5, spraying water tank: 6 meter length, for big diameter, we may need to equip 2 sets or 3 sets of spraying water tank  6, haul off machine: for different diameter, we may equip different type of haul off machine, such as double caterpillar type, three caterpillar type, four caterpillar type

6, haul off machine: for different diameter, we may equip different type of haul off machine, such as double caterpillar type, three caterpillar type, four caterpillar type  7, cutting machine: high quality cutting machine for non-dust cutting

7, cutting machine: high quality cutting machine for non-dust cutting  8. product stacker: 6 meter length

8. product stacker: 6 meter length