Total line:

Part 1,SJSZ-65/132 conical double screw extruder 1,Mould and sizing sleeve :

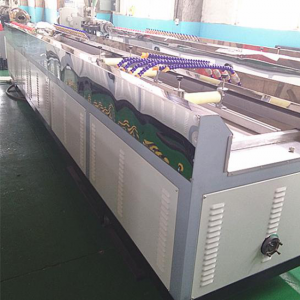

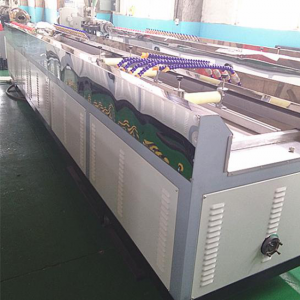

2,vacuum sizing device:

3,Hauling off device:

4,Cutting device

5,Control system of total line :

Part 2,Auxiliary machinery: 1, SHRL—200/500 material mixing device

2,SWP360 crusher:

| 1, Used condition :380—420V/3phase /50HZ |

| 2, Suitable material:PVC powder and the accessory material (we will supply the formula to you ) |

| 3, Applicant:PVC window and door profiles |

| We will supply the mould and sizing sleeve according to the samples . | |

| As the samples | For the acoustic lining : one mould, cause the final product is big |

| For the smaller pieces such as pinch plate , double mould | |

| Can produce the pinch plate two pieces together | |

| The total length of vacuum sizing device : 6000mm |

| Material of water container : stainless steel |

| The joint of cooling water pipes : quantity : 20 piecesThe joint of vacuum pipes : quantity : 20 pieces |

| Landscape orientation adjustment space :80mm Central height adjustment space :80mm Portrait adjustment space :600mm |

| Go forward and recede equipped with auto pushing pole , power : 1.1kw |

| The maximum clamping width : 300mm The maximum clamping height : 120mm |

| Maximum traction : 30000N |

| Hauling off speed : 0-5m/min, can be adjusted must be match with extruder |

| Motor power :3KW |

| With pneumatic fasten adjustment function |

| The diameter of saw blade : 400mm |

| Maximum cutting profile : 250mm |

| Cutting speed : 5m/s |

| Motor power :2.2KW |

| Schneider low-voltage electric applicant ,OMRON intelligent temperature controller , Siemens speed frequency regulator |

| Function : To make the PVC powder together with accessory materials |

| Total volume : for hot mixing device 200L ; for cold mixing device :500LValid volume : for hot mixing device 150L ; for cold mixing device :320L |

| Stirring blade :2 pieces for hot mixing device , 1 piece for cold mixing device |

| Material input at one time : 65KG |

| Rotary speed of hot mixing stirring blade :475/950 r.p.m Rotary speed of cold mixing stirring blade : 90 r.p.m |

| Material mixing time : 6-10 minutesMaterial cooling time :8-12 minutes |

| Heating mode : auto friction or electric heatingCooling mode : water circulate |

| Motor power : 30/42KW ; capacity : about 350kg/h |

| Moving blade : quantity : 3 piecesFixed blade : quantity :2 pieces |

| Diameter of crushing chamber : 360mm Diameter of crushing sieve :10mm Diameter of crushed scrape : 3-5mm capacity : 300-400kg/h |

| Motor power : 11kw |